5 ways Undersealing your car just got even better

5 ways Undersealing your car just got even better

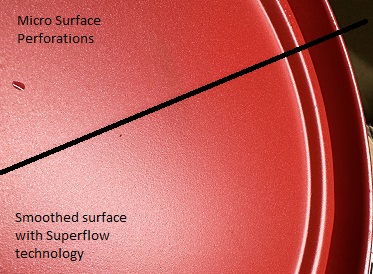

This is a new version of WAR I’m working on. Applied with our heavy texture powercans, you can see it’s very “non textured” ��

There’s many pro’s and cons to different finishes, the viscosity, how much it creeps etc etc etc.

Using superflow technology (essentially allowing war to flow rather than build), will make several small

Improvements.

Higher grade underseal finish

By increasing WAR’s ability to flow it self levels tremendously well. This now provides us a perfect base for a higher grade underseal finish. Leave as is, lacquer it, or Combine with UP for a show grade but durable underbody finish. Preparing WAR once fully cured for a lacquer is also easier as the finish has less of a profile for abrasives to contour too.

Hydrophobic Underseal

Hydrophobicity improves with a smoother finish, less water sat around, more beading, less surface area for moisture to “grab” onto. WAR has always been a hydrophobic underseal, its just now even better. Previously you could get a smoother finish like this, but the reduction in Dry Film Thickness per coat (DFT) wasn’t really with the effort. You had to lay up extra coats through HVLP to achieve the required film build.

Self Cleaning Chassis & underbody

having a self cleaning chassis & underbody means less work is generally put into keeping them clean. This leads to less abrasion and wear and tear on the coating. Same as per above, these properties will further assist WAR’s ability to mitigate mud/ dirt buildup on a chassis, closing the gap to how effective UP zero prep is in this regard. Dirt also harbours mositure so any coating that attracts dirt and muck, and doesnt actually actively try and combat it, can act as a catalyst for future corrosion. We do not sell any coatings that stay sticky for this reason.

Minimum coating DFT

Surface defects. When applying via a Schutz gun, a mistake that can be made is not applying enough product. Most Schutz products have a relatively high viscosity. As a result your texture can end up being a surface that has lots of “balls” of paint, mostly joined up, looks good, looks covered. However, because the product doesn’t flow, it doesn’t move to fill in the gaps left from improper spray technique. The result is the surface has peaks and valleys and the valleys may not have enough film build to prevent moisture getting to the surface (you want around 80 microns minimum DFT at the lowest point for war). by taking the peaks and putting them in the valleys we end up with a more uniform coating film build. So long as enough product has been applied overall your looking at a more reliable sealing coating VS a higher build textured coating.

With WAR superflow the risk of this scenario is massively reduced. However, conversely the risk of a general lack of product being used slightly increases, as even if you apply an insufficient amount, it will flow out and cover the surface- we call thios stretching the product out. It’s still very important to use enough product, but it’s less important to create the perfect spray finish from the gun, as war will now finish the job for you, provided there is enough local paint.

So your looking at a coating that now cleans even easier, is easier to apply, looks after your underbody better, is easier to live with, looks better, and COSTS THE SAME. we call that a win/ win. WAR Superflow will be available for purchase shortly.

Can’t wait to try it

This is great, loving the finish. Can I use UP over the top of this as a sacrificial layer?

Yes. Zero Prep Underbody Preservation and war superflow work great together. They form a strong chemical bond. UIP provides additional protection, and WAR provides a tough aesthetic coating protected by UP. You can also use either of these two underboady coatings independently of each other.,