How to Stripe Coat, and why you should do it.

How to Stripe Coat, and why you should do it.

What is Stripe coating?

Strip Coating is the application of a protective coat to exposed edges such as welds, bolts, seams and anything else vulnerable to corrosion.

Why does stripe coating work?

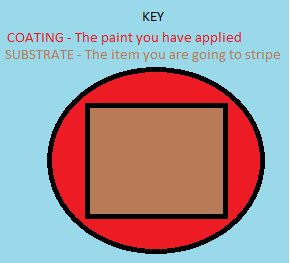

Strip coating is usually the first application of paint to a prepared surface. When you apply paint to a surface, as it cures it thins (how much it thins depends on the solvent content and other factors). Wet coatings, such as traditional paints will naturally "pull" at edges. If you have ever sprayed a surface you will see how much easier it was to get a smooth finish on a Convex shape than a concave one. The extreme of this happens at edges, and what you have is a reduction in film build on the most exposed parts that you are painting- demonstrated in this diagram.

By providing an additional layer of protection to the most vulnerable parts of what you are painting, and then painting "everything" you will help to mitigate this effect and provide more even coverage.

What other benefits does strip coating bring?

Brushing is usually the preferred method. By using mechanical means of application you can work the coating into seams, and hard to reach places, and this also provides you with a coverage benefit. where spraying may not be so able to reach those areas.

What are the disadvantages to strip coating?

There are a few disadvantages to stripe coating, but these are heavily outweighed by the benfits

-

TIME- Its an additional process, so does add to the time taken to complete a task.

-

COST- Adding a process, and also using slightly more product. Again this is outweighed with the increase in longevity.

How to Stripe Coat

Prepare your substrate according to the requirements of your coating. With a brush moving away from the edge coat the following-

-

Exposed edges

-

Seams

-

Angles

-

Welds

-

Bolt threads and heads

-

Captive nuts

-

Brackets

-

Edges of holes

-

Box sections / inner angles/ corners that cannot be effectively sprayed (due to Faraday Cage Effect)

Once all of these items have been coated, observe the coating overcoating time, and then proceed to paint as normal.

Spray stripe coating

YES- you can stripe coat using a spraygun. However, the issue can be angles, access, and faraday cage effect preventing reasonable coverage. Physically applying the stripe coating is more consistent, and the preferred method. Open angles can be stripe coated on larger simple shapes such as I beams, but on something like an underbody or a chassis it is important to do this manually.

TOP TIP :- Observe overcoating times when strip coating, so you don't have to prepare the stripe coated areas for further paint

Faraday Cage Effect

Have you ever washed your car, and sprayed at the right angle so that you get absolutley soaked, and the water come's right back at you? When spraying coatings, through any means this can also happen.

When you spray into a corner or box section, if there is no way for the air / product to escape then it will backup. This will create turbulance and largeley prevent the paint from settling on the substrate. as a minimum you will have reduced film thicknesses, and as a result increase the risk of premature failure later on. DFT (Dry Film thickness) is very important, and integral to longevity of the protection. to get around this you can reduce output of the spraying device such as pressure, Product flow, and alter spraying angles. As an alternative you may be able to charge the paint and attract it to the substrate, but more most people electrostatic spraying is not viable, and simple brush stripe coating is equally as effective.

TOP TIP :- Reduce the thinning efect of the paint on corners by rouding sharp edges with an angel sander

Other means of ensuring even paint coverage

As noted above the "aim" is to have an even paint thickess over the entire chassis/ underbody / substrate (whatever you are painting!). ontop of stripe coating you can also increase you ability to get an even coverage by using different coloured paints. this can as simple as for example a chassis.

-

prepared chassis is a mixture of black, and exposed steel.

-

First coat of primer is RED

-

second coat of primer is Grey

-

top coat first coat is beige, final coat is black.

There are many variations of this, for example we provide our thread dip/ anti-seize in red or black, and it can be overcoated. so after assebly you can choose a cointrasting colour to give you a guide where you need to paint, or highlight work you have done.

Extra Reading